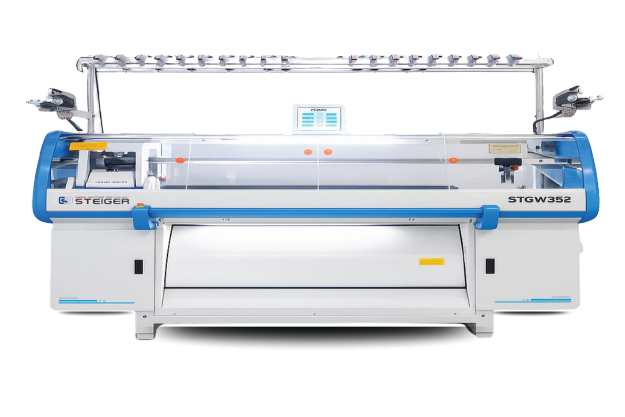

STEIGER STGW352

Steiger STGW 352 Flat Knitting Machine Overview

The Steiger STGW 352 is a high-performance computerized flat knitting machine developed under the Steiger brand by Ningbo Cixing Co., Ltd. It is designed for fully fashioned knitwear production, offering precision, speed, and versatility for modern textile manufacturing. This model is particularly well-suited for sweaters, collars, scarves, and shoe uppers, with a focus on efficiency and pattern complexity.

Key Technical Specifications

| Feature | Description |

|---|---|

| Model | STGW 352 |

| Knitting System | Single carriage with triple knitting systems |

| Needle Bed Width | 52 inches |

| Gauge Options | 7G, 12G, 14G |

| Knitting Speed | Up to 1.7 m/s |

| Yarn Feeders | 2 × 8 yarn feeders (left and right), total 16 |

| Needle Selection | 8-section electronic needle selection |

| Stitch Density Control | 32-segment electronic control with fine subdivision (range: 0–650) |

| Sinker System | Crossed sinker driven by stepping motor, adjustable for different fabrics |

| Transfer Capability | Front and back transfer, independent of carriage direction |

| Roller Device | High-order roller for smoother, more even fabric take-down |

| Motor System | Electric motor-driven connecting rod for precise direction changes |

| Yarn Control | Integrated scissors and clamps for automatic yarn cutting and holding |

| Data Input | USB and computer connection for direct pattern input |

| Safety Features | Auto-stop for yarn break, overload, needle break, fabric rollover, etc. |

| Power Supply | Single-phase, 50–60 Hz |

| Machine Weight | Approx. 1145 kg |

| Dimensions (L×W×H) | 2970 × 940 × 2010 mm |

Performance Highlights

- Triple System Carriage: Enables complex patterning, such as jacquard, intarsia, pointelle, and tight tuck, in a single pass.

- Dynamic Stitching: Allows for variable stitch density across the same row, enhancing design flexibility.

- Innovative Yarn Management: Reduces waste and improves production efficiency with precise yarn control.

- High-Speed Output: Optimized for industrial-scale production with minimal downtime.

- User-Friendly Interface: Supports intuitive pattern input and real-time monitoring.

Ideal Applications

- Fully fashioned sweaters

- Collars and cuffs

- Scarves and gloves

- Shoe uppers (flat knit)

- Fashion accessories and intarsia designs.